The Refit of SV Swan: First Leg of My New Journey

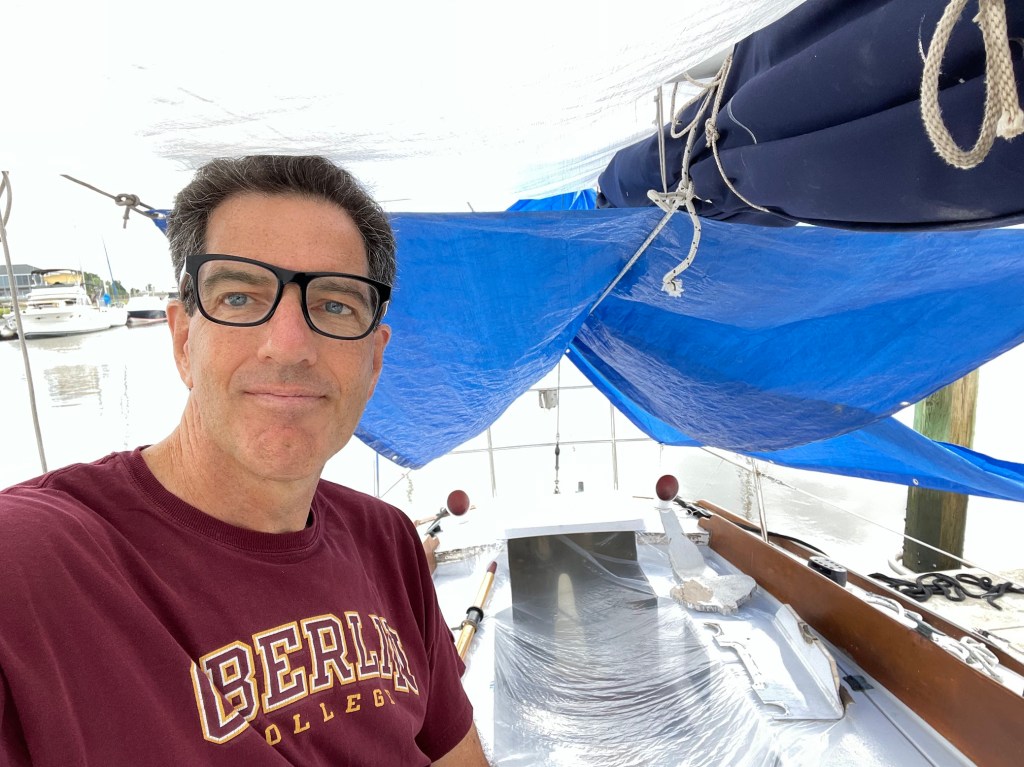

In 2022 and 2023, I worked with accomplished sailor and boat-builder, James Baldwin, for about twenty months to refit and modify my 1980 Cape Dory 36, Swan, for offshore voyaging. Simplicity and seaworthiness was the overriding theme, and now seeing Swan back in her element in the wind and the waves, I can see the effort was a success.

Swan was delivered to Brunswick Landing Marina in Brunswick, Georgia in April 2022. After re-stepping the mast and moving her to Frederica Yacht Club at nearby St. Simons Island, James and I began the work in earnest from the start of May. We worked for five months at Frederica and then moved the boat about fifteen miles north to Two-Way Boatyard, where we worked with the boat on the hard for another eight months through May 2023. Then it was back to Frederica where we worked through the remainder of 2023. James and I generally took one day off a week and otherwise worked nine to five every day. It was tough, and for me, it seemed I was always doing something for the first time, which added another layer of intensity to the experience. As we worked away, it was difficult for me to grasp that the project would someday be done and Swan would return to the water for sailing. There was just so much to do. It was a marathon. It required persistence and patience and a conviction that the small daily advances we were making would eventually lead to the finish line. Somehow they did, and the result has exceeded my expectations. Swan has been reborn as a top-class voyager for the single-handed sailor, and we are now embarking together on the next leg of the journey, this time under sail.

Swan Refit Video Series by James Baldwin

On his Atom Voyages Youtube channel, James has posted a library of videos documenting the many sailboat refit projects he has completed. He made a series of videos about the Swan refit which can be viewed via the following links:

Cape Dory 36 Sailboat Refit Part I

Diesel to Electric Outboard Motor Conversion – Cape Dory 36 Refit Part II

Installing a Solar Arch – Cape Dory 36 Refit Part III

Electric vs. Gas Outboard Sea Trials – Cape Dory Refit Part IV

Solar Charging Dual Bank 12V and 48v Lithium Batteries – Cape Dory Refit Part V

Takacat 260s Dinghy and ePropulsion Spirit Electric Outboard Demonstration

Sailboat Electric Propulsion with Gas Generator (Cape Dory 27 & Cape Dory 36)

Cape Dory 27 Voyager Edition Refit Tour (advance to minute 20:00 for footage with CD36 Swan)

Cape Dory 36 Refit Tour – Part VI

The Swan Refit in Images

The Refit Project List

- removed the diesel engine and fuel tank (Perkins 50 HP diesel)

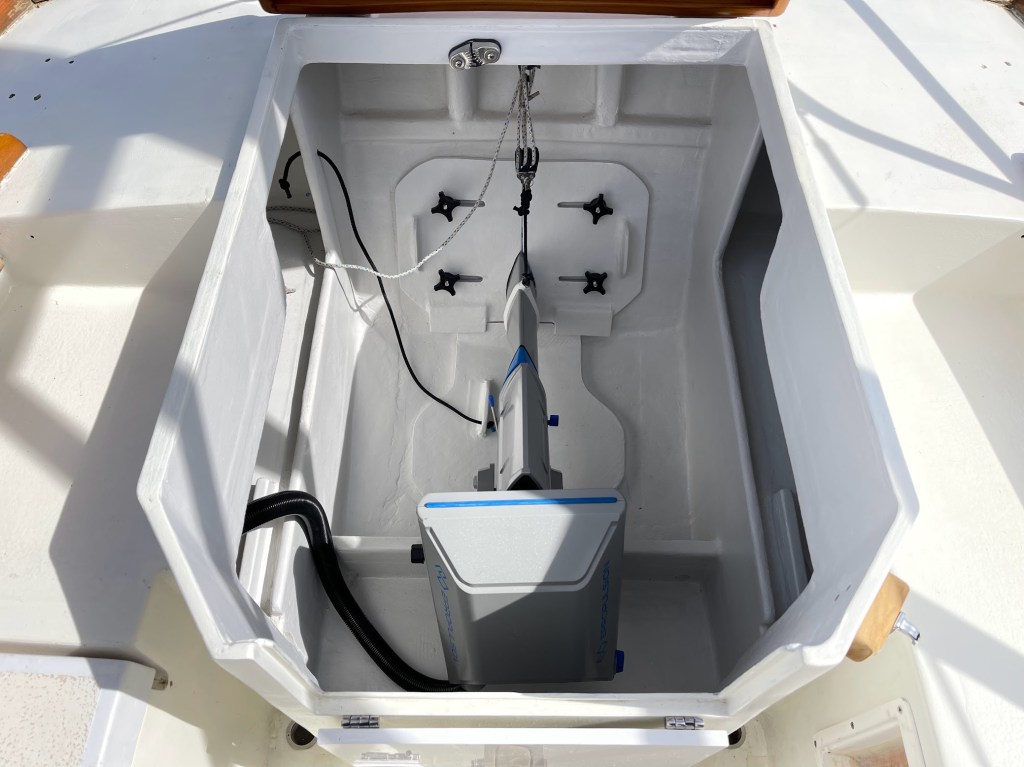

- built a new outboard engine well in the transom that can accommodate either an electric or gas outboard (ePropulsion Navy 6.0 electric and Tohatsu 9.8 gas)

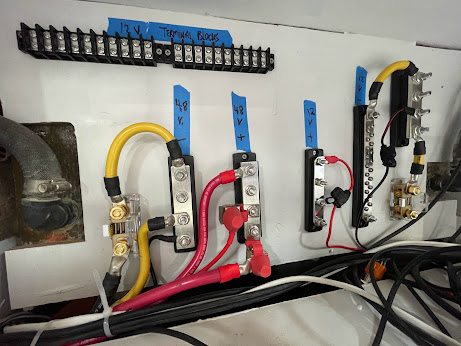

- converted the original well for the diesel engine into a large storage locker and a new battery compartment to accommodate the house battery and two 48v lithium ion batteries for the electric outboard

- converted the wheel steering to tiller steering

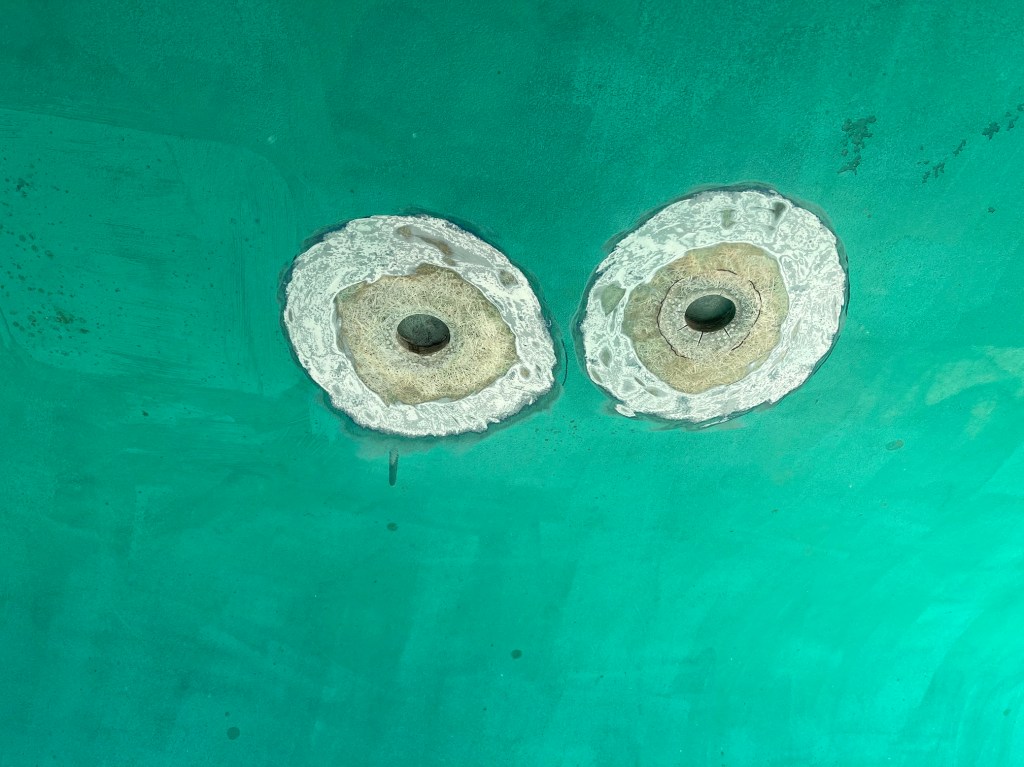

- removed the propeller and sealed the aperture between hull and rudder

- installed a Monitor windvane self-steering system

- installed a Pelagic autopilot self-steering system

- installed a Tower-in-a-Box solar arch over the cockpit

- installed two 200-watt solar panels on the solar arch

- installed two new depth sounders

- replaced the tricolor and anchor light

- installed new cockpit instruments including a new compass and the displays for the ePropulsion Navy 6.0 electric motor, the Raymarine depth sounder, and the Pelagic autopilot

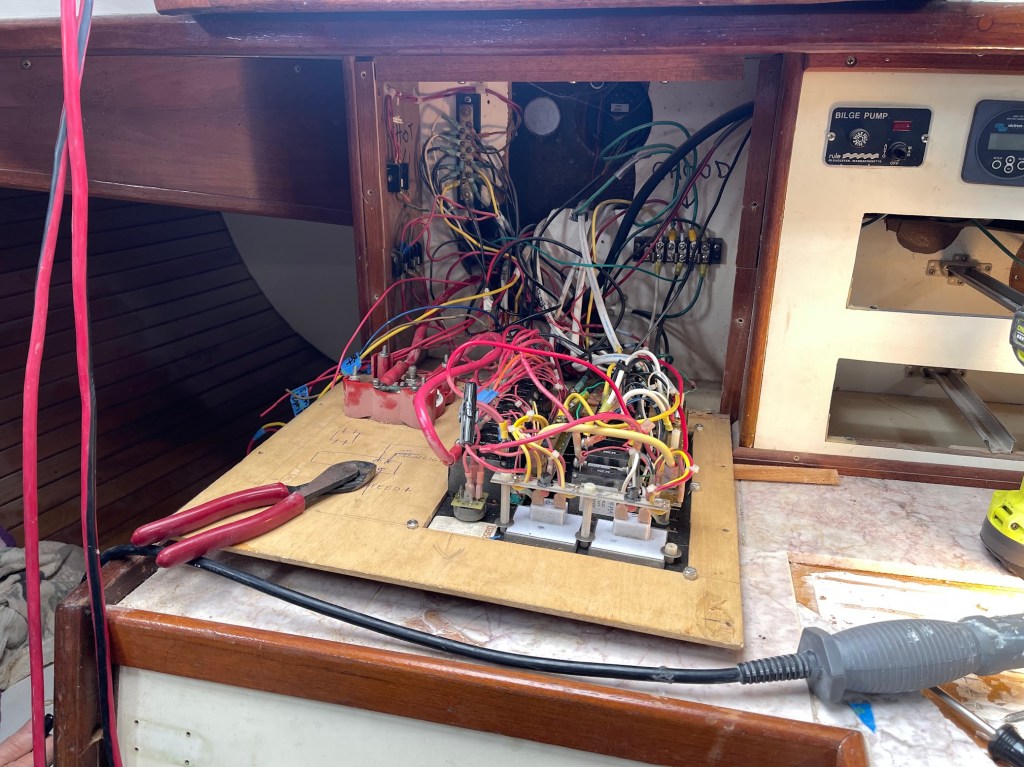

- replaced both electric panels and all AC and DC wiring throughout the boat

- replaced all plumbing, including installation of manual pumps for head and galley sinks and internal drainage hoses and valves for the chain locker, watertight cockpit lockers, and watertight compartment surrounding the rudder shaft

- replaced the standard marine head, electric macerator, waste tank and associated y-valve with a tailor-designed dry head that is simple and easy to maintain

- removed the water heater installed between the diesel engine and rudder shaft

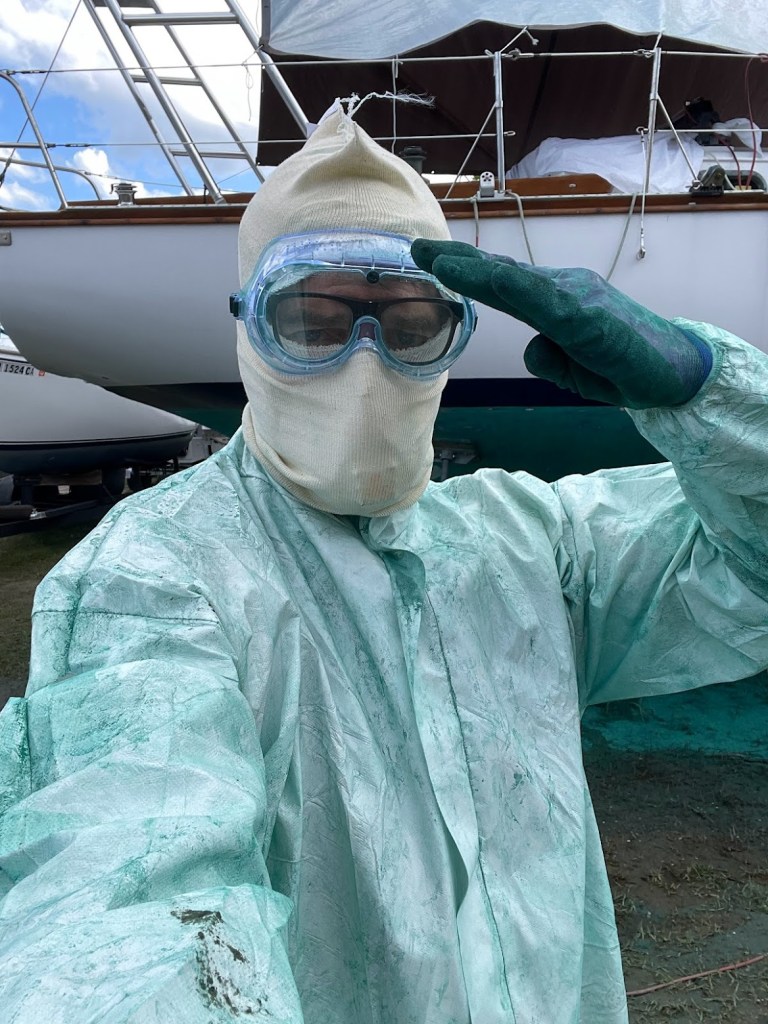

- finished the rebuild of the cockpit area and engine well with fiberglass, fairing compound and epoxy paint

- replaced the cockpit sole and reversed the angle of slope so that drainage is to the aft rather than forward

- primed and painted the entire cockpit and stern area with two-part epoxy paint

- painted with 2000E epoxy primer all interior and exterior lockers, including a new locker under the port berth where the waste tank had been located, a new locker where the diesel engine had been located, and the port and starboard cockpit lockers

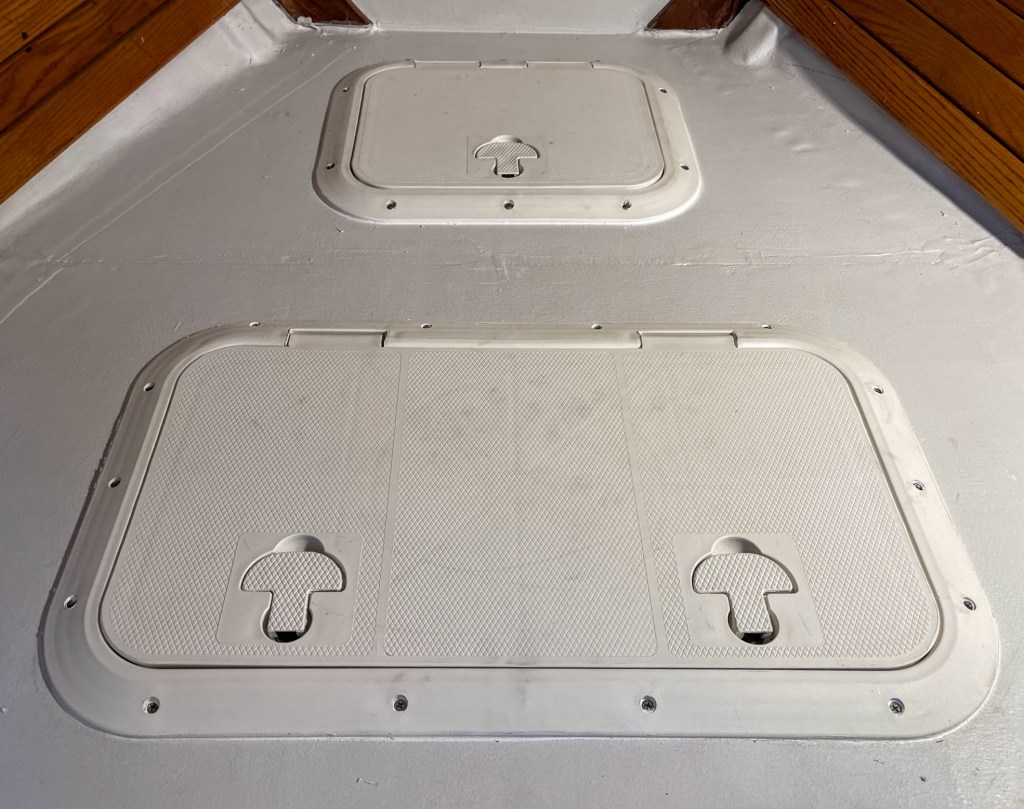

- built a watertight compartment for the rudder shaft with easy access hatches for inspection or repairs

- built two watertight lockers in the v-berth

- rebuilt the port and starboard cockpit lockers to make them watertight, including reconstructing the watertight seals on the locker covers using thickened epoxy and rubber gasket

- redesigned and rebuilt the chain locker so that it is watertight

- installed watertight Beckson plates in the starboard and port cockpits to allow access to the battery compartment and other watertight cockpit compartments

- plugged ten unnecessary through-hulls and removed the seacocks

- sealed an additional seven unneeded holes above the water line

- installed above-water through-hulls for manual and electric bilge drainage

- installed two new seacocks, one for galley sink drainage and one for galley sink raw water intake

- plugged and painted multiple unneeded holes in the transom and stern area

- finished the transom with new coats of primer and marine paint

- installed a Lofrans Royal manual windless

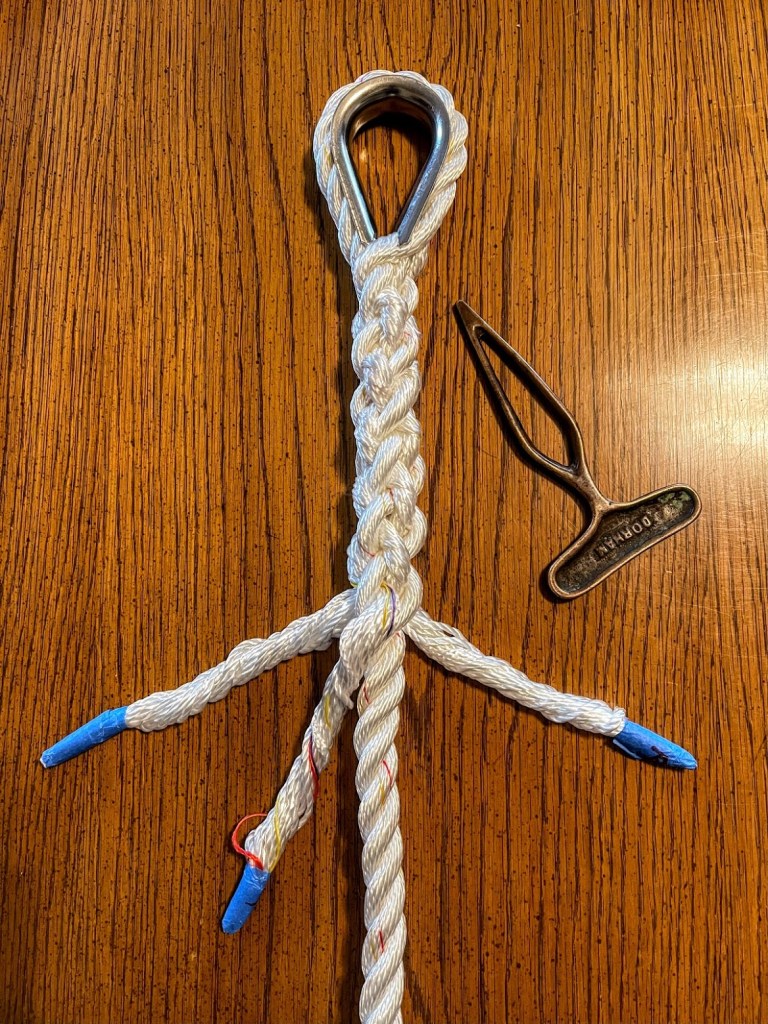

- replaced the original small anchor with a 45 lb. Rocna and the rope rode with 150 feet of 3/8″ chain plus 100 feet of new rope

- added a secondary anchor and third anchor (Guardian G-37 and West Marine Traditional 26)

- removed unnecessary fittings on the foredeck and transom and repositioned the bow cleats

- repositioned and re-bedded all remaining deck fittings, including blocks for mainsail and staysail

- installed starboard and port chainplates on the stern hull exterior to attach a drogue

- installed a new winch for the staysail sheets

- raised the gooseneck to provide more head clearance in the cockpit for the boom

- re-bedded most of the original Spartan bronze port lights with butyl

- installed new Dyneema lifelines

- replaced all standing rigging, including the four lower shrouds, two intermediate shrouds, two upper shrouds, forestay, inner stay, and back stay

- replaced the bobstay

- replaced the jib furler with a Harken Mark IV unit 1

- installed a dodger

- installed a new lightning ground plate on the hull and ground cables connected to mast and shrouds

- added two hundred pounds of additional ballast in the bilge, consisting of 125 pounds of lead bars and 75 pounds of lead pellets, and sealed the ballast in polyester resin

- replaced and re-bedded port and starboard handrails on the coach roof and re-bedded ceiling handrails in the main cabin

- built and installed a new mahogany tiller

- removed, refinished, and re-bedded all teak on and around the sea hood

- repainted the sea hood

- revarnished the teak around the companionway

- redid all non-skid deck surface with grey KiwiGrip

- replaced the mainsail, staysail, Genoa and storm jib with new sails and added a new asymmetric spinnaker

- sanded the bottom and painted it with two coats of hard coat anti-fouling paint followed by three coats of ablative paint

- installed new Formica on the galley counters

- rebuilt the linen closet and painted the interior with 2000E epoxy primer

- cut four new floorboards in the cabin and v-berth sole to provide easy access under the sole from bow to aft

- installed knock-down proof latches in all seven floorboards below deck and barrel bolts on other doors and panels for same purpose

- replaced the entire sole in the v-berth

- installed new flooring in the v-berth and galley to match the teak and holly pattern in the main cabin

- rebuilt the head compartment, including reconstruction and repainting of cabinets and stowage areas, painting of grey non-skid on the sole, and installation of a ventilation fan

- added a Takacat 260 S Catamaran dinghy powered by an ePropulsion Spirit 1.0 electric motor